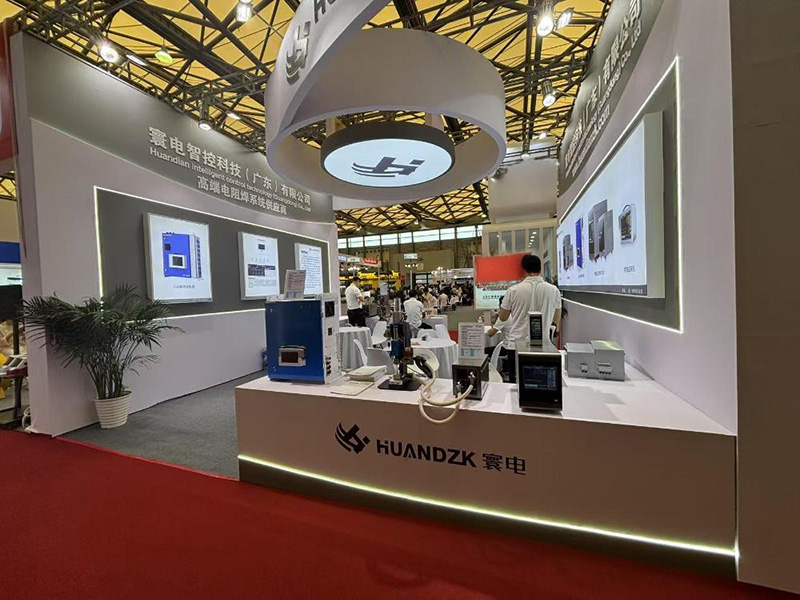

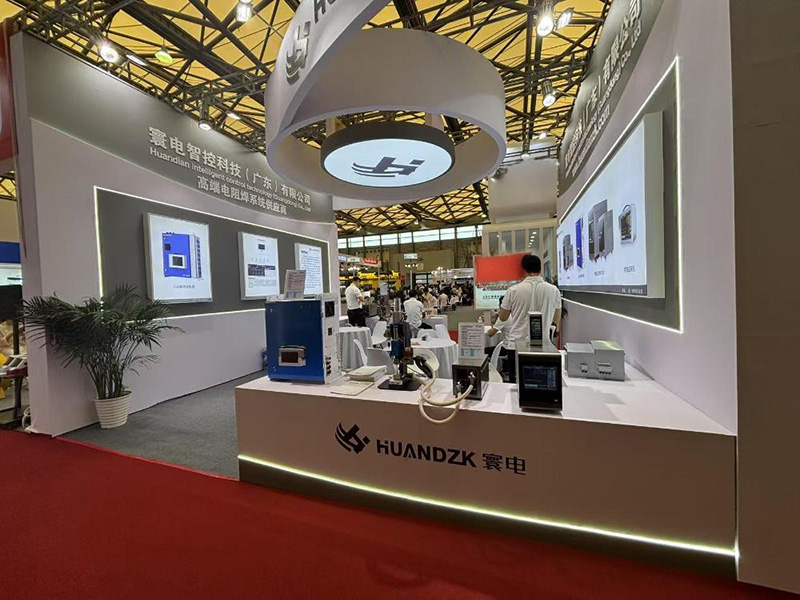

From May 17 to 20, 2025, the Beijing Essen Welding and Cutting Exhibition was held in the Shanghai New International Expo Center. As China's leading manufacturer of resistance welding power supplies, we brought a number of innovative products to the exhibition, showing the latest research and development results in the field of welding control and intelligent manufacturing to global users.

At this exhibition, we focused on exhibiting precision welding power supplies, servo controllers, MFDC medium-frequency transformers, and 620T series controllers for the automotive welding industry; we also exhibited HD-100B and HD-400B monitors designed for welding quality monitoring, attracting a large number of domestic and foreign customers to stop and visit and have in-depth exchanges.

Our welding power supply fully supports multi-stage discharge control, and has independent adjustment functions for each stage of slow rise and slow fall parameters, which effectively improves weld formation, significantly reduces welding spatter, and improves overall welding stability. The power supply integrates up to 22 fault diagnosis and welding protection mechanisms, and cooperates with intelligent alarm functions to ensure high safety and controllability of the welding process.

In terms of welding frequency selection, we pioneered the support of free switching of multiple frequency bands from 1kHz to 5kHz, which can flexibly adapt to different welding scenarios and material requirements. Compared with traditional products, welding power supply has achieved a leapfrog improvement in control accuracy and response speed.

We also pioneered the use of servo motor control function as standard to achieve multi-stage precise control of welding pressure and flexible adjustment of welding head reset distance, which completely solves the problem of excessive impact of traditional cylinder welding heads, and is particularly suitable for projection welding processes that require higher pressure control.

In addition, the power supply system has powerful welding data monitoring and quality traceability capabilities, with a control accuracy of up to 0.2ms, low heat generation, and a smaller heat-affected zone, which not only improves the appearance consistency of the weld, but also enhances the welding strength and stability, and significantly reduces the welding defect rate.

The welding monitor HD-400B is compatible with a variety of resistance welding equipment types, including AC spot welders, DC/AC inverter spot welders, transistor spot welders, and energy storage spot welders. The monitoring function covers current, voltage, power, and power-on time, and can be equipped with multi-dimensional parameters such as pressure, displacement, temperature, and air pressure to achieve all-round quality control. Welding analyzer equipment built-in multi-mode counter can accurately count the output and welding times, helping to efficiently manage the production process.

In the future, we will continue to deepen the research and development of welding power supplies and intelligent control systems to promote China's manufacturing welding technology to a higher standard.