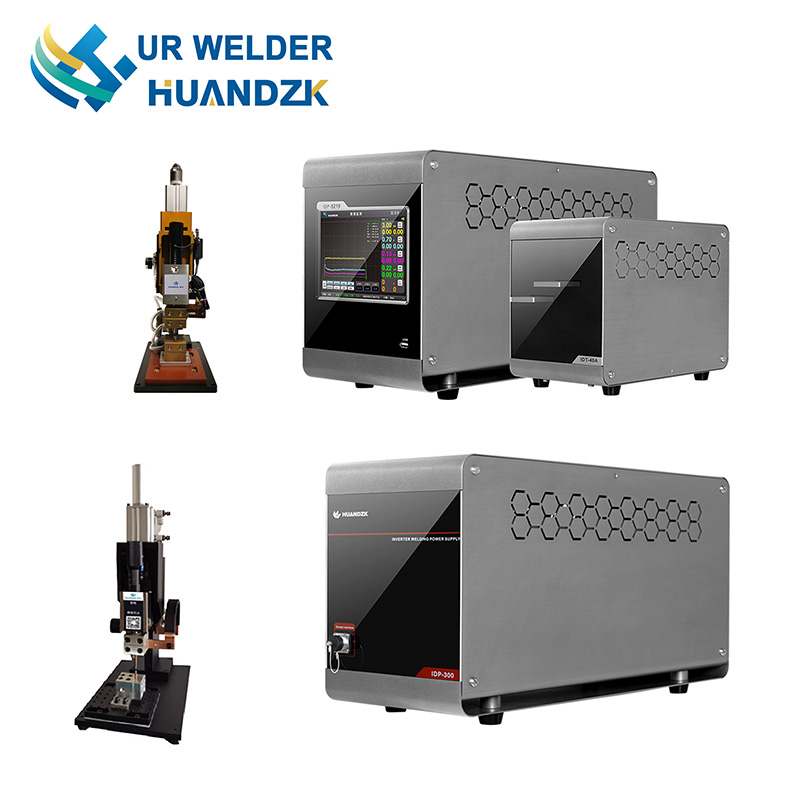

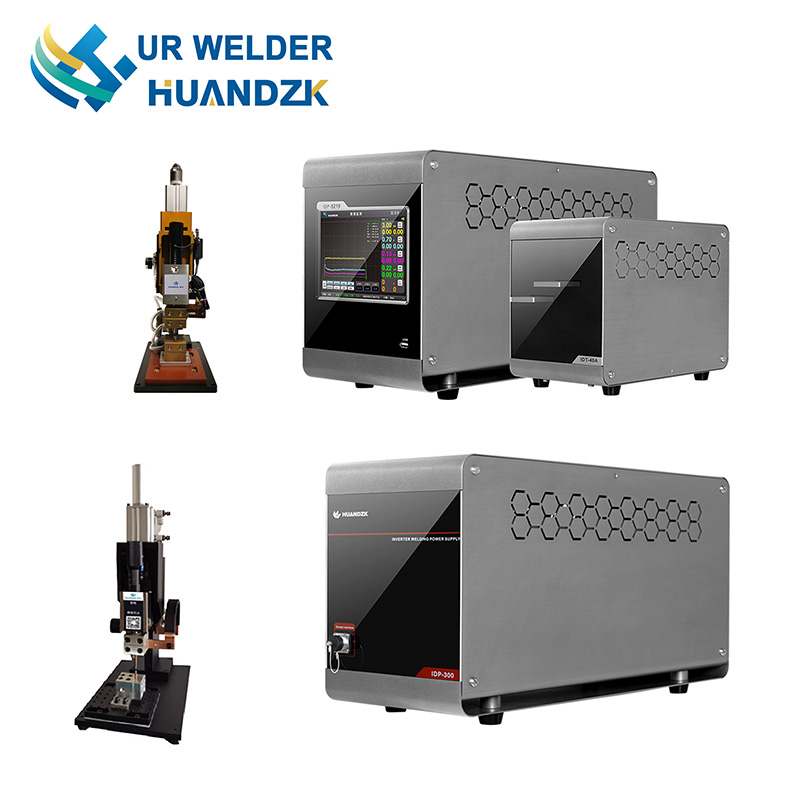

Under the wave of intelligent manufacturing, the precision and stability of welding technology have become the key to improving the quality and efficiency of the manufacturing industry. After a year of technical breakthroughs and market cultivation, Precision welding power supply manufacturer launched the IDP series high-frequency precision inverter DC power supply IDP-3420, IDP-5420, breaking through the industry bottleneck with independent innovation and opening a new chapter of intelligent welding power supply.

Technical core: high-frequency inverter and digital intelligent control dual drive

The new generation of power supply deeply integrates high-frequency inverter technology and DSP digital signal processing technology, converting traditional industrial frequency current into high-frequency pulses, and improving energy conversion efficiency by more than 50%. With 0.2 millisecond dynamic response capability, electric resistance welding realizes microsecond-level precise control of welding current and voltage to ensure the consistency of solder joints. The core components are imported high-end brands to ensure the long-term stable operation of the equipment in high-demand scenarios such as automobile manufacturing and 3C electronics, and the failure rate is reduced by 60% compared with traditional models.

Three major innovative advantages: high efficiency, intelligence, and integration

1. Precise intelligent control, quality leap

0.2 millisecond control accuracy combined with real-time data monitoring and quality traceability functions can dynamically optimize welding parameters, and the defective rate has dropped by more than 30%. The uniformity of the appearance of the weld spot has increased by 40%, and the tensile strength has increased by 15%, which is especially suitable for precision welding of new energy battery pole pieces, microelectronic components, etc.

2. Energy saving and consumption reduction, green empowerment

High-frequency inverter technology reduces heat loss by more than 30%, and the intelligent temperature control system further reduces workpiece thermal damage, helping enterprises achieve low-carbon production goals.

3. Compact integration, intelligent interconnection

The volume is reduced by 40%, and lithium welding machine can be flexibly integrated into a robotic arm or automated production line. Supports upper computer group network control, realizes centralized management of multi-device data and remote process optimization, seamlessly connects to the MES/PLC system, and provides underlying hardware support for the "dark factory".

Application scenarios: enabling high-end manufacturing upgrade

From new energy vehicle battery module welding to aerospace precision parts processing, the Huandzk IDP series covers multiple fields with stable performance. In large-scale production of home appliances, hardware, etc., resistance spot welding machine's high-speed continuous operation capability can increase production capacity by more than 20%, while reducing operation and maintenance costs by 15%.

Future layout: data-driven new welding ecology

Huandzk is exploring the application of AI algorithms in welding quality prediction, pushing the industry from "experience-oriented" to "data-driven". As the company's technical director said: "Intelligent welding is not only a technology upgrade, but also a reconstruction of manufacturing logic." Huandzk takes "precision intelligent control" as the core, and continues to provide high-reliability solutions to global customers, helping Chinese smart manufacturing to seize the high ground in the global industrial chain.