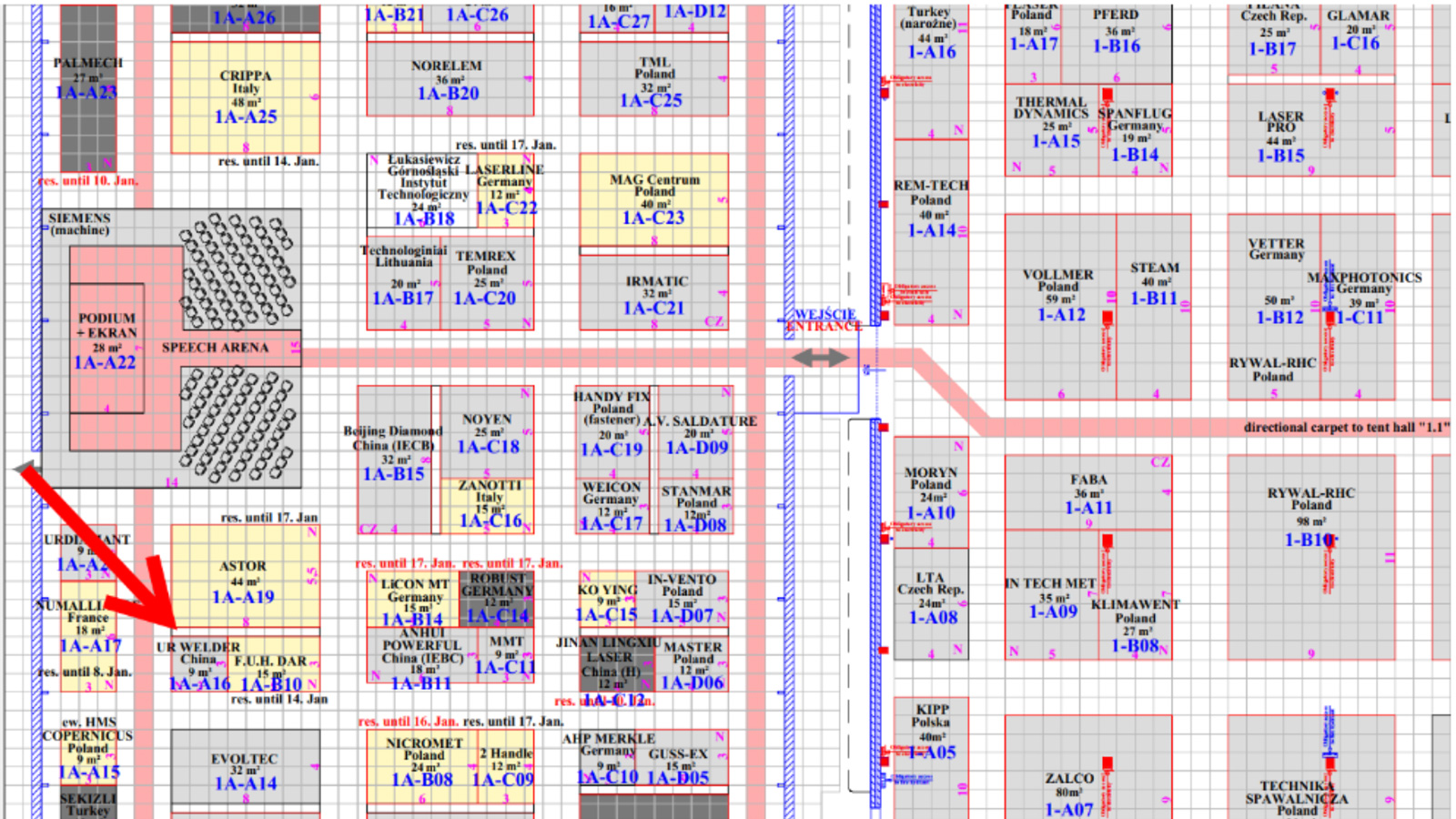

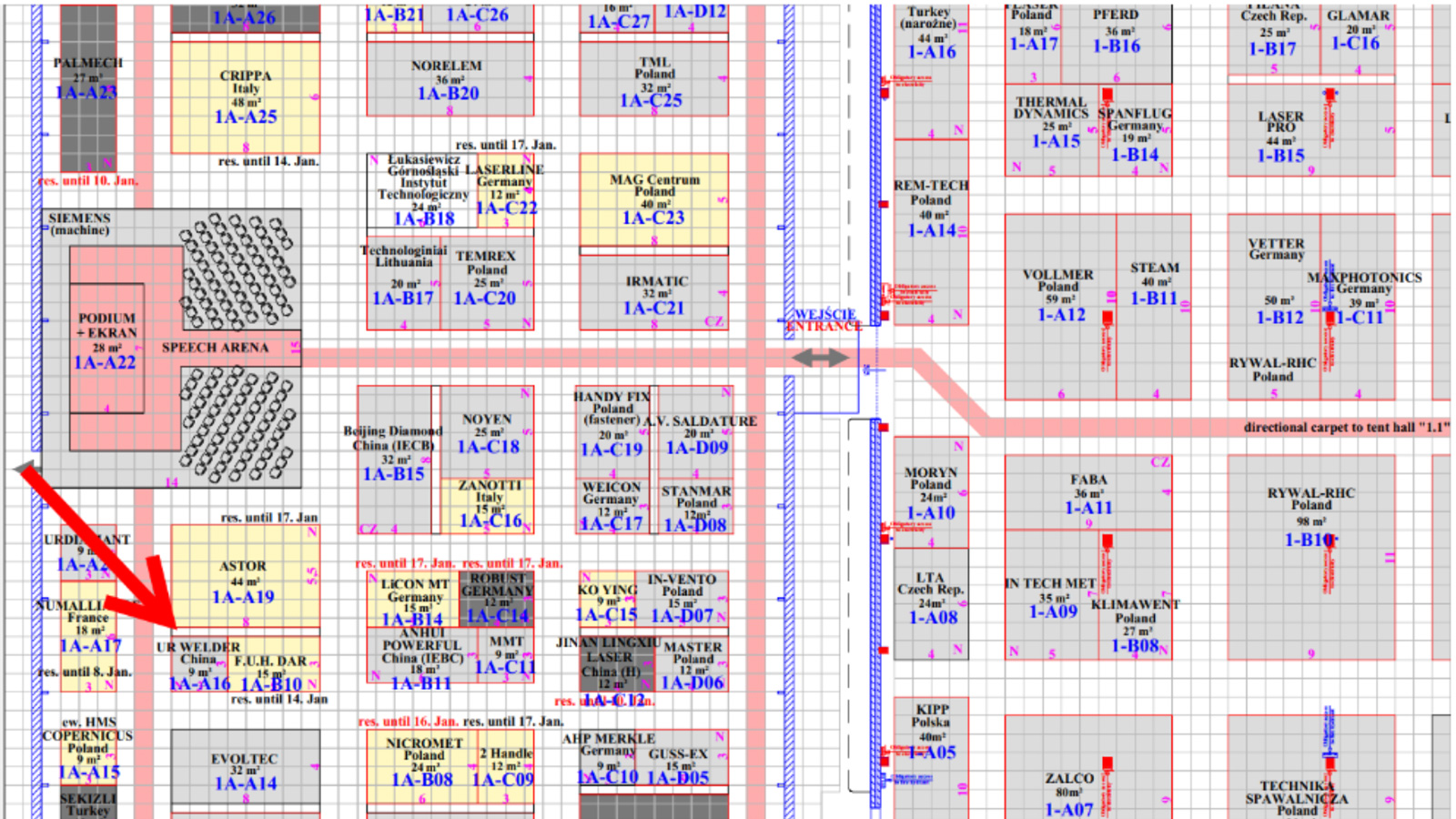

INDUSTRIAL SPRING KIELCE POLAND (25-28.03.2025)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

The Polish International Welding Technology and Equipment Exhibition is held every spring at the Kielce Tagy Exhibition Center and is one of the most prestigious professional exhibitions in the industry. The exhibition not only showcases the latest welding technology and equipment, but also perfectly combines with the long-term metal processing technology exhibition held at the Kielce Tagy Exhibition Center, becoming an important platform for the global welding industry.

As China's most technologically advanced and powerful welding power supply manufacturer, Huandian will participate in this exhibition and showcase our core products and innovative technologies in the field of welding. Our product line includes ultra-precision welding power supplies, precision inverter welding power supplies, high-power high-frequency DC welding power supplies, high-frequency transformers and other hardware essences. At the same time, we also provide intelligent solutions such as multi-functional HD-400B-all-rounds-comprehensive-welding-monitor.html">welding monitors, welding networking group control systems and welding quality monitoring systems.

IDP series precision welding power supply - industry-leading technology and innovation

The IDP series precision welding power supply is a high-frequency inverter DC power supply independently developed by Huandian, which is widely used in the field of high-precision welding. This series of welding power supplies uses imported high-quality components to ensure the reliability and stability of the product. At the same time, the IDP series welding power supply also applies the most advanced inverter power supply technology and DSP electronic control technology, with the following significant advantages:

1. Welding quality control capability

The IDP series welding power supply has powerful welding quality control functions and supports multiple real-time data monitoring, including current, voltage, power, pressure, displacement and other key welding parameters. Through the precise control and monitoring of these data, the consistency and high quality of the welding process are ensured.

2. High precision and low damage

The control accuracy is up to 0.2 milliseconds, with low heat generation and low workpiece damage. The weld spot has excellent appearance, high welding strength, strong welding stability and low welding defective rate. This series of products is compact and easy to integrate with the automation system, meeting the high requirements of modern industry for welding accuracy and efficiency.

3. Intelligent solution

Through the host computer welding network group control system and real-time welding quality monitoring system, the IDP series welding power supply can realize the visualization, dataization and intelligence of the welding process, providing more accurate process control and quality traceability.

4. Multi-stage discharge and welding pre-inspection function

The IDP series supports multi-stage welding discharge, and can set the slow rise and slow fall function of each stage of welding separately, which helps solve the problem of welding spatter and ensures welding stability. At the same time, the pre-inspection function before welding can effectively avoid problems such as electrode explosion caused by insufficient head pressure.

5. Electrode grinding function

The built-in electrode grinding function will issue a warning prompt when the electrode is used for a set number of times to help users grind the electrode in time to ensure that the welding effect is not affected.

6. Real welding waveform display

Equipped with a 7-inch high-definition touch screen, built-in oscilloscope and detector functions, inverter welding power supply can display the current, voltage, power, resistance waveform and other data of each welding in real time. This function is not only convenient for analyzing welding quality, but also helps customers monitor welding consistency and debugging.

7. Innovative servo motor control technology

The IDP series welding power source adopts servo motor control technology for the first time to achieve accurate and adjustable multi-stage welding pressure. This technology solves the problem of instantaneous impact force generated during traditional cylinder welding, especially in projection welding process.

8. Breakthrough inverter frequency technology

Using the industry-leading 1kHz to 5kHz frequency free switching technology, compared with similar products, the IDP series power supply can provide higher control accuracy and faster response speed, adapt to a variety of complex welding conditions, and further improve welding quality and efficiency.

At this Polish International Welding Technology and Equipment Exhibition, Huandian will showcase these innovative products and look forward to communicating and cooperating with global customers and industry experts. Through continuous innovation and technological breakthroughs, we are committed to providing global customers with more efficient, more stable and more intelligent welding solutions to promote the development and progress of the welding industry.

If you are interested in learning more information or arranging business negotiations during the exhibition, please contact us and look forward to meeting you at the exhibition!