As China's largest and technologically advanced welding power supply manufacturer, we will present our independently developed welding innovative technologies and core products at this exhibition. Today, we will focus on introducing a highly anticipated product for you - HD-400B All-round Welding Detector.

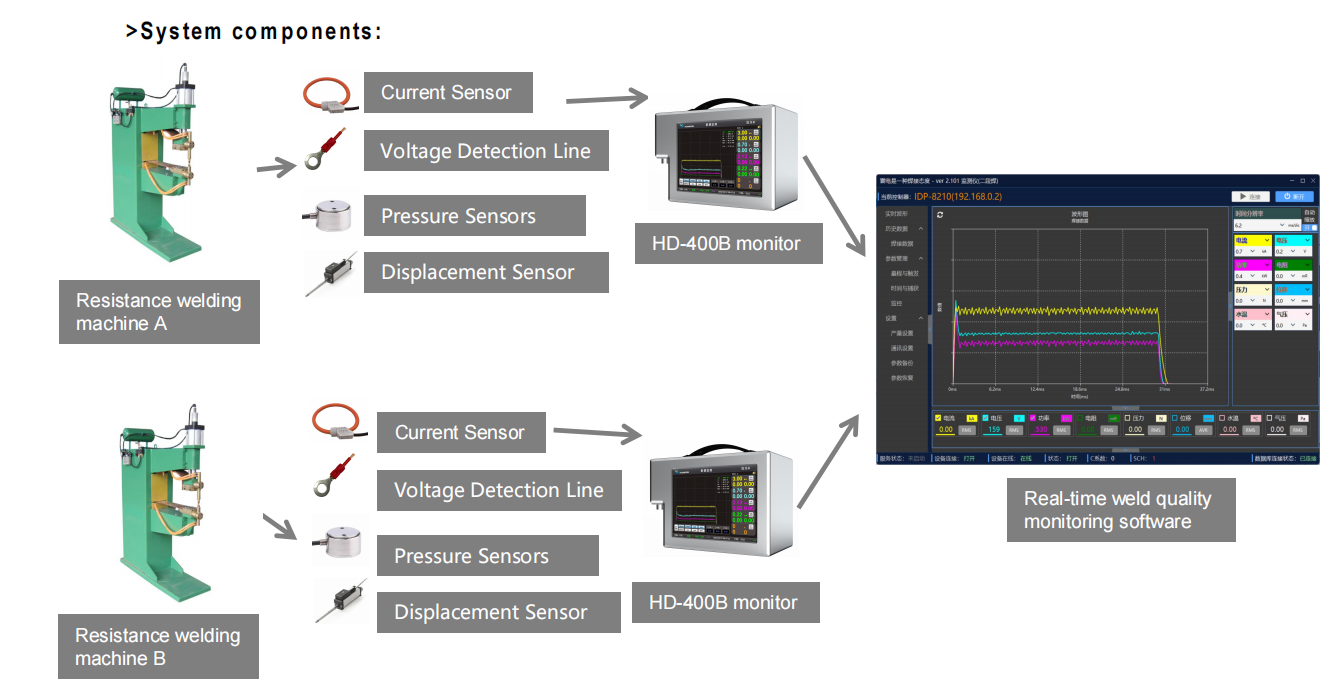

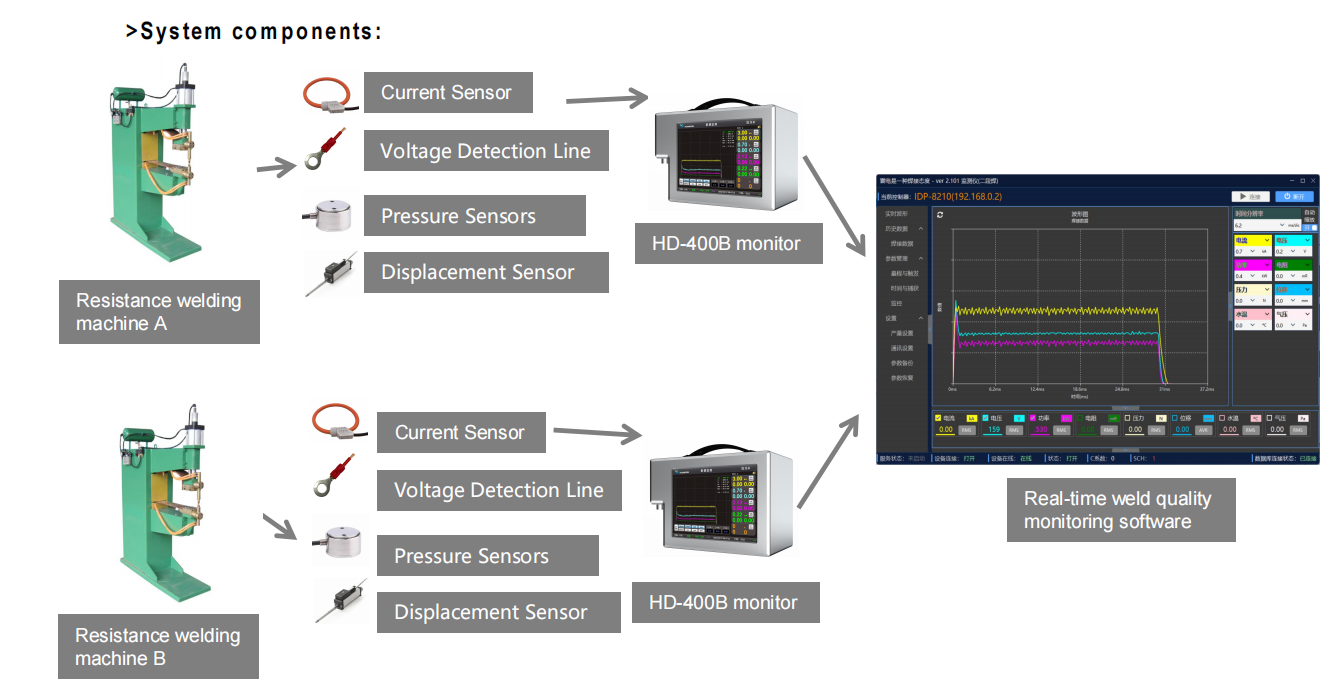

HD-400B All-round Welding Detector is a resistance welding detection device independently developed by Huandian Company. Welding analyzer equipment is manufactured with high-quality imported components to ensure the high reliability and stability of the product. Welding testing equipment uses digital technology to achieve accurate collection and comprehensive monitoring of key values in the welding process. Whether welding leakage detector is a single or multiple resistance welding equipment, welding quality inspection device can collect key data such as welding current and voltage in real time, and provide multi-functional support such as display, over-limit alarm and network communication. At the same time, current meter for welding machine has powerful data recording and historical tracing capabilities, which effectively improves the standardization and welding quality of welding operations.

Main features of HD-400B:

1. Wide adaptability

Welding detector is suitable for various types of resistance welding machines, including AC spot welders, DC inverter spot welders, transistor spot welders and energy storage spot welders, etc., to meet the needs of different welding equipment.

2. Comprehensive monitoring capability

In addition to monitoring current, voltage, power and power-on time, welding monitoring device can also monitor pressure, displacement, temperature, air pressure and other data to achieve more comprehensive welding process monitoring.

3. Intelligent quality judgment

Supports the upper and lower limit settings of key values (such as current, voltage, power, pressure, displacement, etc.), and has the function of welding quality judgment. Once unqualified welding is detected, the equipment will immediately alarm and automatically mark unqualified products.

4. High-definition touch display

Equipped with an 8-inch high-definition touch screen, spot weld testing equipment displays the current, voltage, power and other waveforms and corresponding data of each welding in real time. The intuitive data presentation makes the operation more convenient and the welding process is clear at a glance.

5. Powerful data management

Built-in powerful database, which can store millions of welding data and historical alarm information, supports U disk export to generate tables, and facilitates users to monitor and trace quality.

6. Flexible communication interface

Equipped with a variety of I/O interfaces, compatible with RS-232, RS-485, Ethernet and other communication protocols, can be easily integrated into automated production lines.

7. Real-time quality monitoring

Provide real-time welding quality monitoring to ensure that each welding can achieve the best results, help users optimize production processes and improve product quality.

HD-400B all-round welding detector provides a new intelligent solution for welding quality management with its excellent performance and rich functions. We look forward to sharing more technical highlights with you at the 2025 Kielce Welding Technology Exhibition in Poland. Welcome to our booth to discuss the latest technology and future development in the field of welding with us!