In the field of resistance welding, microcomputer spot welding controllers are gradually becoming the core equipment of welding processes with their excellent performance, precise control and diversified functions. The microcomputer spot welding controller has an 8-inch high-definition touch screen, which provides users with an intuitive and friendly operation interface. Through the touch screen, operators can view key data such as current, voltage, power, resistance waveform, etc. during the welding process in real time. This not only makes the welding process more transparent, but also helps operators to make precise adjustments based on real-time data to optimize the welding effect.

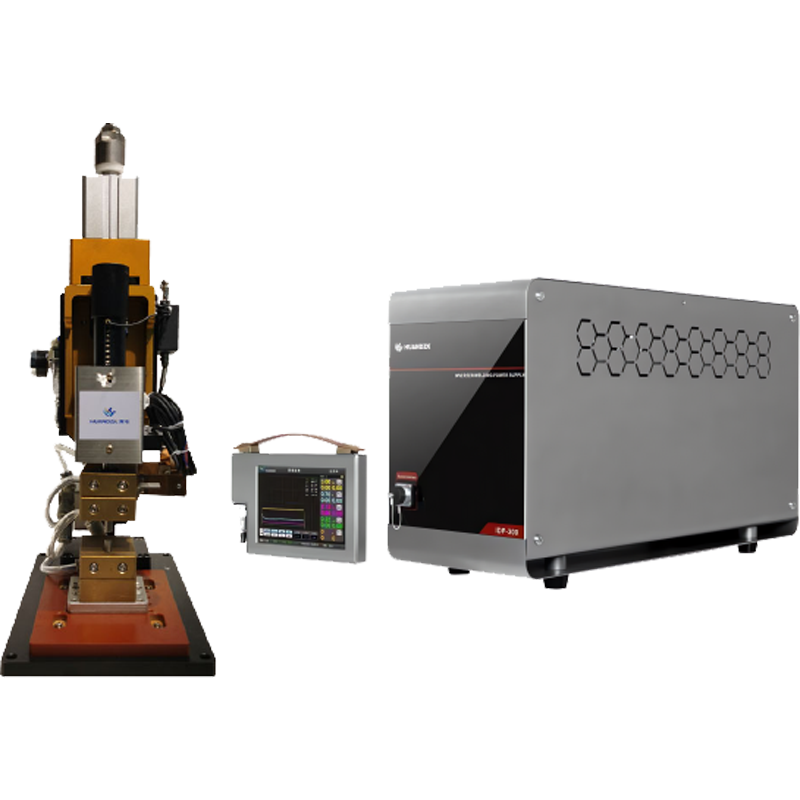

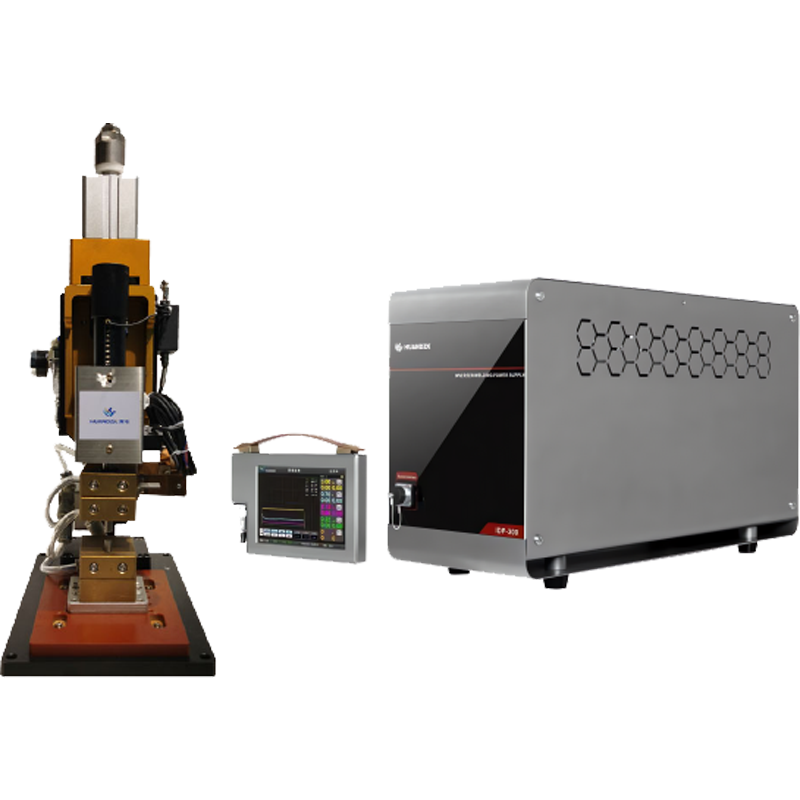

In addition to the humanized design of the operation interface, Huandian's microcomputer precision spot welding controller also has a variety of control modes. Modes such as constant peak current, constant secondary current, constant secondary voltage, constant power, constant pulse width and mixed control enable the controller to cope with various complex welding requirements. Whether it is welding thin plates, thick plates or special materials, the microcomputer spot welding controller can provide precise control to ensure welding quality and stability.

In addition, powerful fault diagnosis and protection functions are also a highlight of the microcomputer spot welding controller. Through the built-in multiple fault diagnosis functions, the controller can monitor abnormal conditions in the welding process in real time, such as welding defects, equipment failures, etc. Once an abnormal situation is found, the controller will immediately take corresponding protective measures to ensure the safety and stability of the welding process. This intelligent fault diagnosis and protection function greatly reduces the risk in the welding process and improves production efficiency.

For integration with external automation systems, the microcomputer spot welding controller also performs well. It provides a rich I/O interface and supports multiple communication protocols such as RS-232, RS-485, Ethernet, etc. This enables the controller to easily connect and control external equipment such as robots and production lines to achieve automation and intelligence of the welding process. In terms of data management, the microcomputer spot welding controller supports the storage function of welding records and fault information. Through real-time export and reading of U disk, users can easily track and analyze data and problems in the welding process. This not only helps enterprises to monitor and track quality, but also provides strong support for improving welding processes and improving production efficiency.

It must be said that the microcomputer spot welding controller also has the function of upper and lower limit monitoring and setting of current, voltage, and power. Users can set monitoring values as needed, and when the actual output value exceeds the set range, the system will issue an alarm prompt. This function ensures that the welding process is always carried out within the controllable range, effectively avoiding potential safety risks. In addition, the microcomputer spot welding controller also supports multi-stage discharge settings and the adjustment of slow rise and slow fall functions. These functions help optimize the welding forming effect, solve the problem of welding spatter, and improve the stability and quality of welding.

Whether it is automobile manufacturing, aerospace or home appliance production, the microcomputer spot welding controller can provide efficient and stable solutions for various complex welding tasks. In short, the microcomputer spot welding controller has a high-definition touch screen, diversified control modes, powerful fault diagnosis and protection functions, rich I/O interfaces and communication protocols, welding records and fault information storage, current, voltage, power monitoring settings, multi-stage discharge and slow rise and slow fall functions, high frequency adjustable and control accuracy, etc., which not only improves welding quality and production efficiency, but also reduces production costs and safety risks.