Precision DC spot welding machine has good welding effect, and the time adjustment resolution of precision spot welding machine is more accurate and the control accuracy is high. The response speed of feedback control of precision spot welding machine with high service quality is significantly faster, and the output stability is good. The output current of precision spot welding machine is pulsating DC, and spot welding machine is continuous DC output under the action of loop inductance, with high thermal efficiency and stable welding heat input. High-quality precision spot welding machine can quickly realize welding operation and ensure more excellent welding. The operation of completing welding in an instant can also ensure that the welding point is more stable. Modern precision spot welding machine improves the system and integrates the needs of environmental protection use, so that there will be no smoke, noise and pollutants in the welding process, thereby maximizing the environmental requirements. Hand spot welder is one of the important manifestations of modern environmental protection production and one of the important means to reduce pollution.

Precision DC spot welding machine has good welding molding, precision spot welding machine has DC output, concentrated heating, and shortened welding time. Therefore, the precision spot welding machine has excellent effect in strong standard welding, and the traceless effect is first-class. Tack welding machine can directly weld computer chassis and other high-end welding. One spot welding machine is now widely used in the welding of some precision instruments.

The precision DC spot welding machine has a better working experience. The transformer of the precision spot welding machine works at a higher frequency with very little loss. The DC output improves the power factor and has obvious energy-saving effect. The structure of the equipment is reasonable and convenient to install. The transformer of the precision spot welding machine is greatly reduced and the equipment is lighter. Therefore, consumers can have better portability when using the precision spot welding machine, and the operation is simpler and can adapt to the application in different environments.

1. Principle of precision DC spot welding machine:

The principle of precision DC spot welding machine is to convert AC into DC for welding through technology. We all know that all factories are using AC because the cost of AC is relatively cheap, which saves a lot of resources for enterprises. However, the advantages of DC are also precision DC spot welding machine's own disadvantages. Because they are complementary, DC is more stable on AC equipment. Like AC welding machines, DC is mainly desktop, usually divided into foot-operated and pneumatic. The welding machine uses DC discharge, which can adopt single pulse, multi-pulse, cycle, time, and other control methods. Resistance welding machine can also be used for single-point welding, continuous welding automatic control, manual control, and diversified specifications. Pin spot welder is mainly used for tungsten, molybdenum, nickel, iron, copper, aluminum, silver, stainless steel, etc.

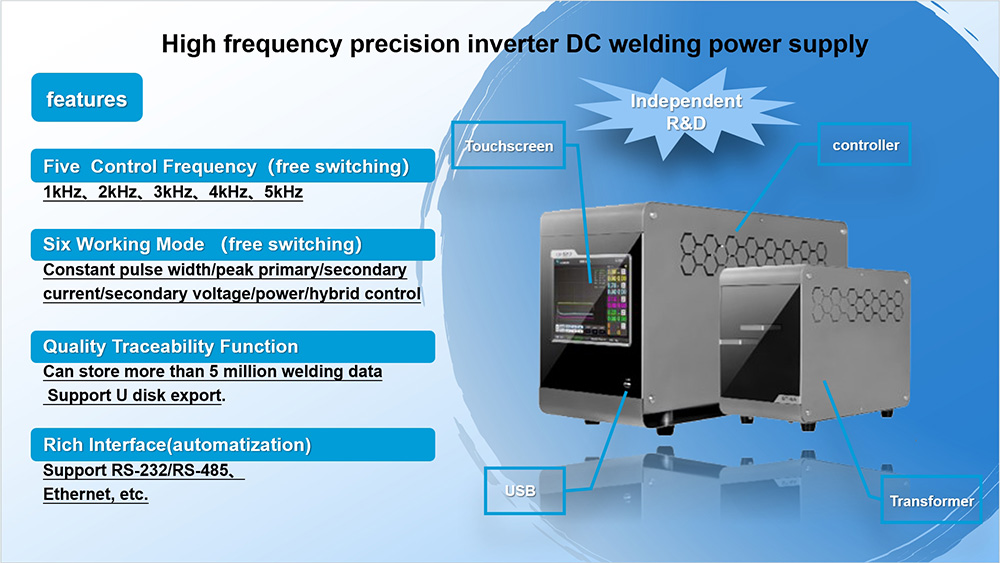

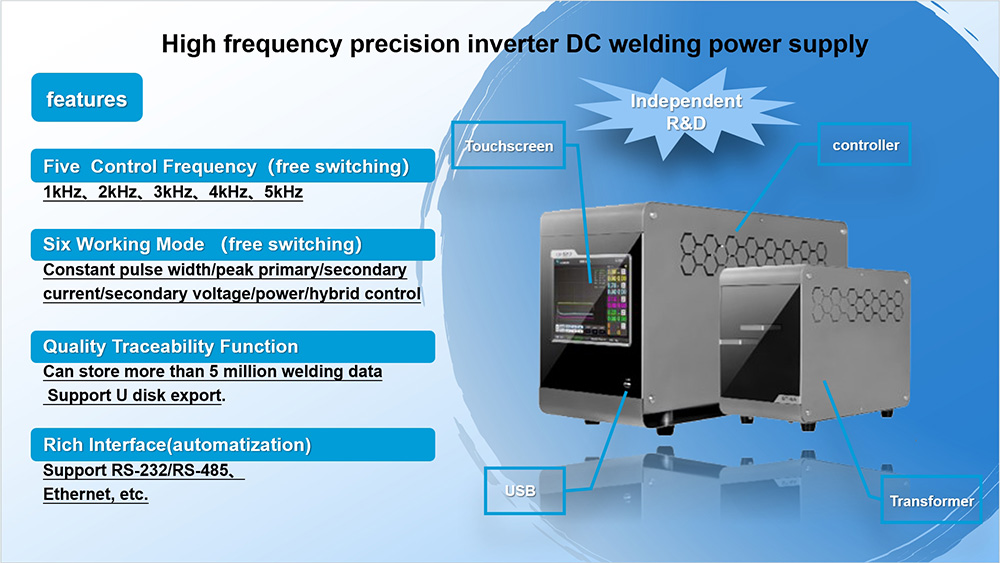

2. Features of precision DC spot welding machine:

A. Output power frequency: 1KHZ, time accuracy is ms level.

B. Up to 15/31 sets of welding specifications can be programmed, 15 sets in fixed point mode and 31 sets in robot mode.

C. Three-stage heating process: preheating, welding, tempering, in which the welding section can define the increasing and decreasing sections by yourself.

D. Programmable output I/0 port; programmable 3-segment output, better adapted to PLC, robots, etc.

E. Welding point counting function.

Choose precision DC spot welding machine, you will get:

More efficient welding experience.

More accurate welding control.

More environmentally friendly production method.

Wider application scenarios.

Precision DC spot welding machine helps you easily achieve high-quality welding!