380V copper wire welding machine, as a model of precision resistance welding technology, is specially designed for copper wire welding. Its excellent adjustment ability allows the current and time to be precisely matched, achieving seamless integration between copper wires, showing the advantages of efficient, fast and stable welding. In the broad stage of electronics, electrical appliances, communications and other industries, it has become an indispensable production tool, leading the trend of innovation in welding technology.

Talking about the advantages of 380V copper wire welding machine, high efficiency, reliability, wide applicability and convenient operation are its four highlights. Compared with traditional welding methods, it is like a skilled craftsman, completing the copper wire welding task quickly and accurately, significantly improving production efficiency. The application of precision resistance welding technology has built a solid line of defense for welding quality, ensuring that the product is reliable and durable.

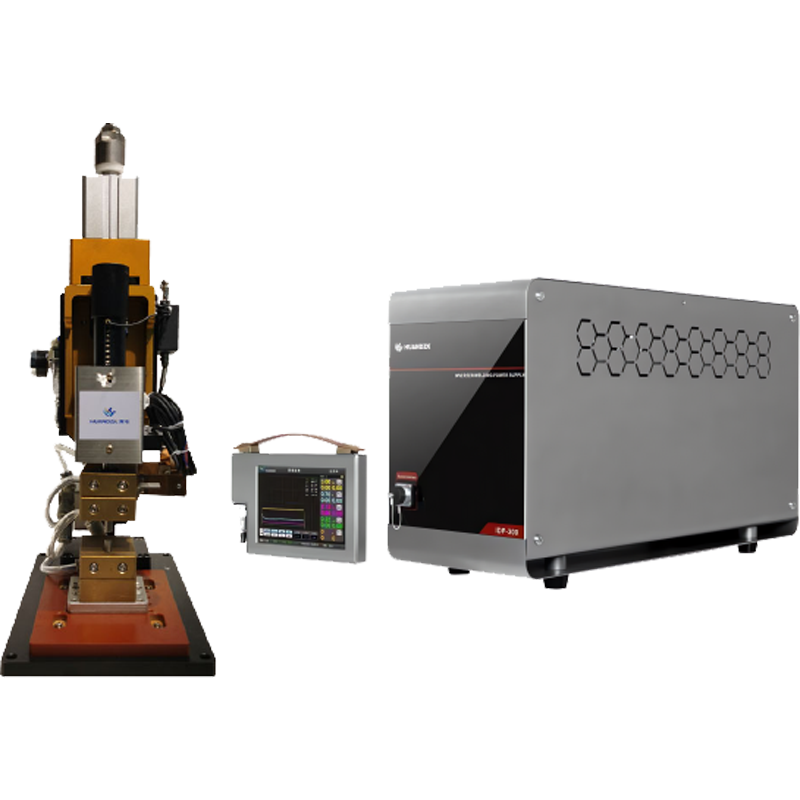

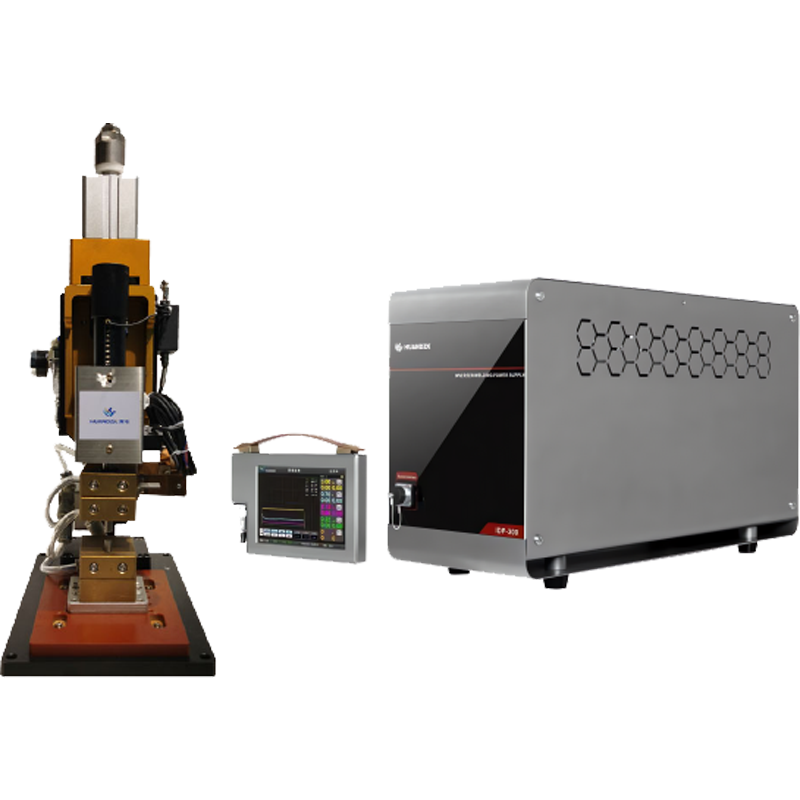

No matter what specifications and materials of copper wire, 380V copper wire welding machine can handle it with ease and meet diverse production needs. And its humanized design makes the operation simple and intuitive, even beginners can quickly get started, effectively reducing labor costs. Take Huandian's 380V copper wire high-precision spot welding machine as an example. Its high-definition touch screen with real-time detection function allows welding data to be clear at a glance; multiple control modes and fault diagnosis systems provide all-round safety protection for the welding process.

Therefore, when choosing a 380V copper wire welding machine, we need to consider power, technical parameters and brand quality. Appropriate power is the cornerstone to ensure welding effect and production efficiency; in-depth understanding of technical parameters can help us accurately set welding parameters according to different materials and specifications; and well-known brands and reliable quality welding machines are the key to ensuring equipment stability and service life.

With the widespread application of 380V copper wire welding machines in all walks of life, choosing the right equipment has become the only way to improve production efficiency and ensure product quality. IDP series inverter DC welding power supply, as Huandian's ingenuity, has set a new benchmark for welding quality control with its imported components, advanced inverter technology and DSP electronic control technology. Its high-precision control, low heat generation, small workpiece damage, excellent solder joint appearance and strong welding stability have jointly created a shining pearl in the welding field.