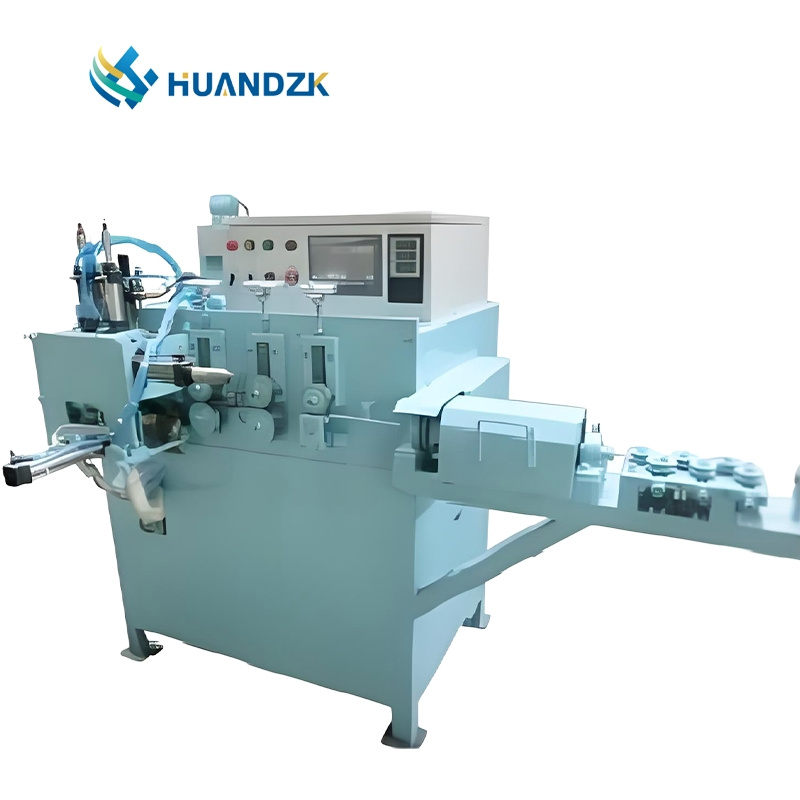

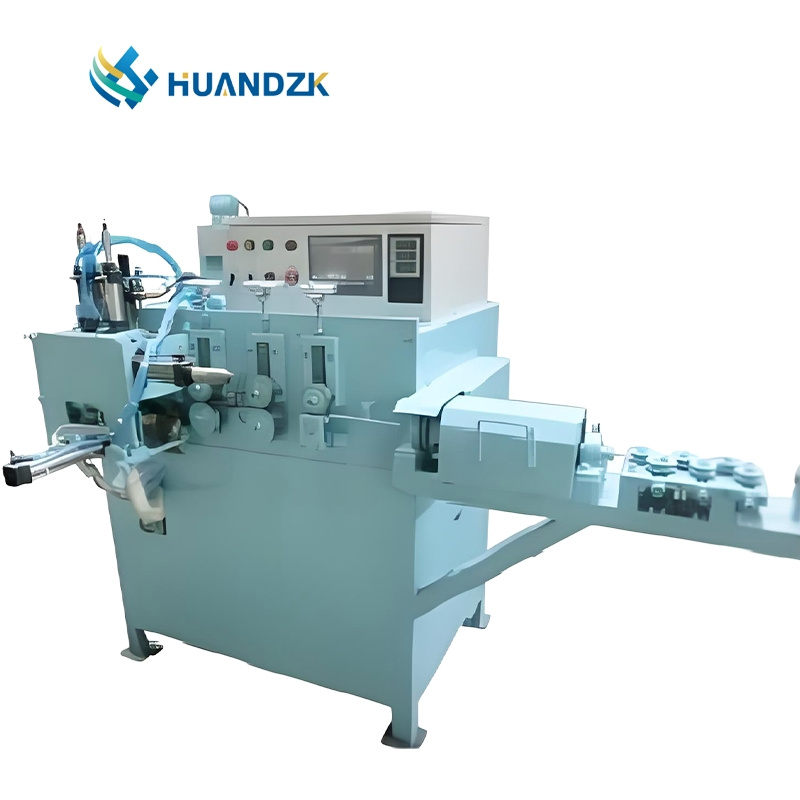

High-Performance Resistance Seam Welding Solutions for Modern Metal Fabrication

In today’s precision-focused manufacturing world, metal joining technologies must deliver exceptional consistency, high strength, and long-term durability. Advanced welding systems—especially those designed for resistance seam welding—have become essential across automotive components, stainless steel products, electrical enclosures, tubing, and industrial metal fabrication. A modern resistance seam welding machine brings unmatched control, stability, and production speed, making it one of the most reliable tools for factories seeking both accuracy and productivity.

Unlike conventional welding approaches, resistance seam welding provides a continuous, leak-proof, and highly uniform weld. When performed by a properly optimized resistance seam welding machine, the process delivers strong mechanical properties, minimal deformation, and superior appearance. This is why resistance seam welding is widely used to replace slow manual welding methods, particularly in applications requiring airtight sealing or structural integrity.

Why Resistance Seam Welding Machines Lead Modern Production

A high-grade resistance seam welding machine offers advantages that traditional welding systems cannot match. The machine applies controlled pressure and passes electrical current through rolling electrodes, creating continuous overlapping weld nuggets. This method of resistance seam welding results in a repeatable weld line that is strong, clean, and thermally stable.

Key advantages include:

-

Exceptional weld uniformity

-

High-speed continuous welding

-

Low thermal distortion, ideal for thin materials

-

Long electrode life and low maintenance

-

Compatibility with automated lines

Because manufacturers increasingly demand a combination of spot welding and seam welding, modern equipment integrates both functions. The ability to switch between spot seam welding and continuous seam modes saves time, reduces equipment investment, and supports flexible production layouts.

Spot Welding and Seam Welding in a Single Platform

Many production lines require both discrete weld points and continuous seams for different components. A machine capable of spot welding and seam welding dramatically enhances manufacturing capability. For example, electronic enclosures may require spot seam welding at corners and continuous seam welding along edges. Automotive mufflers and steel pipes often rely on a combination of both processes.

With multifunctional systems, operators can shift between spot welding and seam welding without changing machines. This reduces downtime and ensures consistent welding parameters across the entire production process. When integrated into automated systems, the combination of spot welding and seam welding drives reliable output with minimal operator intervention.

Spot Seam Welding – Precision for Small Components

Spot seam welding is especially valuable for parts requiring small, uniform, and repeatable welded sections. It uses the same principles as resistance seam welding but applies intermittent or controlled pulses for partially stitched seams. Industries such as appliances, sensors, battery components, and precision metal fittings depend heavily on accurate spot seam welding.

A high-quality resistance seam welding machine ensures that each spot seam weld achieves the ideal nugget size, penetration, and bonding strength. This eliminates weak points and improves long-term reliability in products exposed to vibration, electrical load, or structural stress.

Stainless Steel Butt Weld Applications

Stainless steel is a common material in food equipment, medical devices, industrial tubing, exhaust systems, and pressure vessels. Producing a strong and clean stainless steel butt weld is critical for structural strength and corrosion resistance.

Resistance seam welding is especially effective for creating airtight and visually clean stainless steel butt weld joints. Because the heat input is controlled and concentrated, the welded area maintains excellent mechanical durability without excessive discoloration or warping. When using an advanced resistance seam welding machine, manufacturers can achieve a stainless steel butt weld that requires minimal finishing and offers long-term performance in high-stress environments.

Why Choose a Modern Resistance Seam Welding Machine

Today’s manufacturing environments demand reliable, fast, and accurate welding methods. A state-of-the-art resistance seam welding machine delivers precisely that. Whether the application involves resistance seam welding, spot seam welding, or a combination of spot welding and seam welding, these machines provide stable heat control, advanced monitoring, and consistent output.

For businesses working with stainless steel, aluminum, mild steel, or specialty alloys, the ability to create a strong stainless steel butt weld or continuous seam weld is essential. Investing in modern resistance seam welding technology results in: