Resistance welding can indeed be used for chip welding, but this process requires a high degree of precision and professionalism. The following is a detailed explanation of resistance welding chips:

1. The basic principle of resistance welding

High efficiency inverter resistance welding machine is a method of welding by applying pressure through electrodes and using the resistance heat generated by the current passing through the contact surface of the joint and the adjacent area. This welding method has the advantages of high thermal efficiency, dense welds, good quality and low cost, so tiny spot welder is widely used in many fields.

2. Application of resistance welding in chip welding

Feasibility:

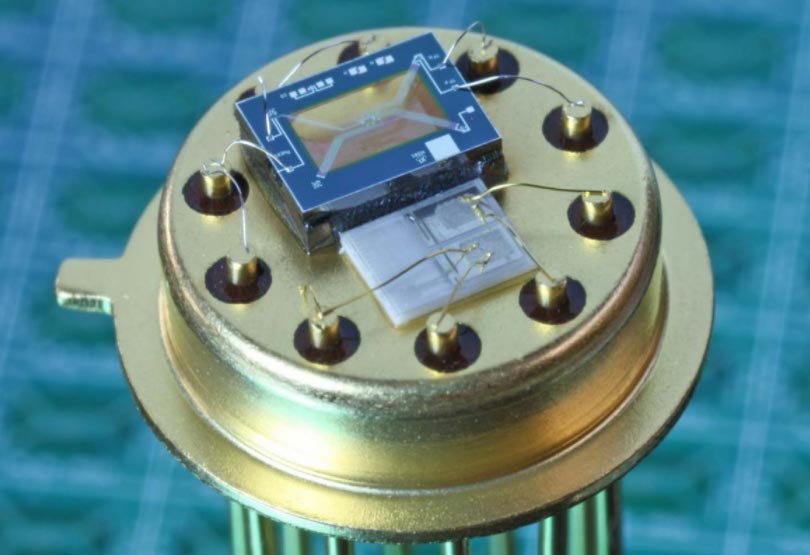

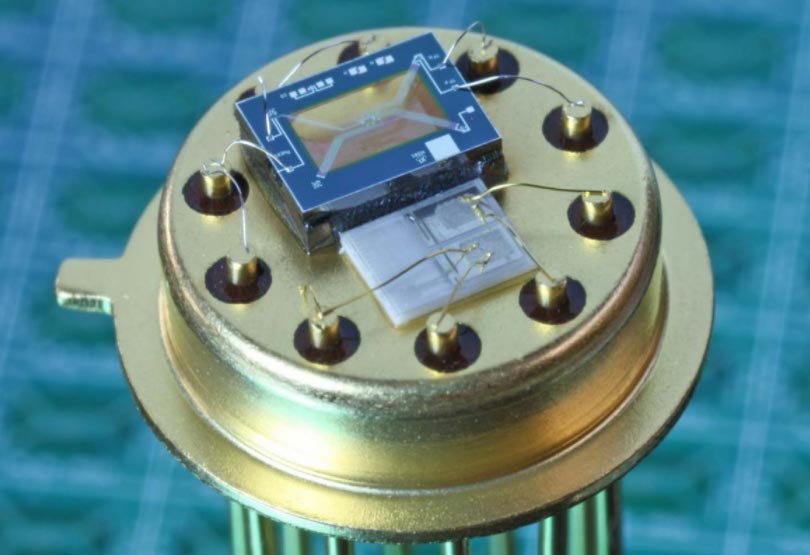

Resistance welding has certain feasibility in chip welding, especially in some scenarios that require high-precision equipment, such as the welding of MEMS sensor chips.

By precisely controlling the welding parameters and selecting the appropriate welding head, resistance welding can achieve a firm connection between the chip and the substrate or other components.

Selection of welding parameters:

Current: The appropriate current intensity needs to be selected to ensure that the heat generated during the welding process is sufficient to melt the welding material, but not too high to damage the chip.

Pressure: The pressure of the welding head also needs to be precisely controlled to avoid excessive mechanical stress on the chip.

Time: The length of the welding time will also affect the welding quality and the safety of the chip, and needs to be adjusted according to the specific situation.

Selection of welding head:

The shape, size and material of the welding head need to be selected according to the characteristics and operation requirements of the chip.

A suitable welding head can ensure the uniform distribution of current and pressure during welding, thereby improving the welding quality and the safety of the chip.

3. Precautions for resistance welding chips

Precise control:

Resistance welding chips require highly precise control, including precise adjustment of parameters such as current, pressure and time.

This requires professional welding equipment and experienced operators to achieve.

Prevent damage:

During the welding process, special attention should be paid to prevent excessive pressure or excessive current of the welding head to avoid damage to the electronic components inside the chip.

At the same time, cnc spot welding machine is also necessary to avoid thermal damage to the chip caused by the heat generated during the welding process.

Environmental requirements:

Resistance welding chips need to be carried out in a dry, dust-free and static-free environment to avoid the influence of environmental factors on welding quality and chip safety.

Subsequent processing:

After welding, the welding points need to be cleaned and inspected to ensure welding quality and chip safety.

If defects are found in the welding points or the chip is damaged, they need to be repaired or replaced in time.

4. Summary

Resistance welding can be used for chip welding, but electric resistance welding is necessary to strictly control the welding parameters and select the appropriate welding head. In actual operation, professional welding equipment and experienced operators are required to achieve precise control to avoid damage to the chip. At the same time, welding operations must be performed in a dry, dust-free, and static-free environment to ensure welding quality and chip safety.

The above information is for reference only. If necessary, résistance spot welding is recommended to consult a professional welding technician or refer to the relevant welding process standards.

Tips:Our core products include ultra precision welding power supplies, precision inverter welding power supplies, high power high frequency DC welding power supplies, high frequency transformers and other hardware essentials; at the same time, we also provide intelligent solutions such as multi functional welding Welding analyzer, welding networking group control systems and welding quality monitoring systems. If you are interested in any of the above products or need further information, please feel free to contact us, or click on the lower right corner to follow our major social platforms.