As the heart of the welding machine, the design of the spot welding machine power supply is inspired by the most advanced spot welding machine principle in the world. It minimizes the swing of the fuselage and significantly improves the control accuracy, thereby greatly enhancing the accuracy of welding and cutting. There is a significant difference between the medium frequency inverter spot welding machine and the ordinary spot welding machine in the transformer current: the former flows through about 50HZ AC, which makes it easier to operate automatic welding. Compared with the 20m standard of the traditional AC welding machine, its performance has been improved by 80% or 20 times, with significant results. However, such high performance also brings an urgent need for more advanced cooling and heat dissipation technology. At the same time, the design of its human-machine interface also keeps up with the trend of the times and shows a cutting-edge sense of technology.

Regardless of the device or circuit being simulated, the dynamic response speed of the medium frequency inverter spot welding machine power supply far exceeds the traditional power frequency rectifier spot welding machine power supply, reaching an improvement of 23 orders of magnitude. The introduction of the capacitor resistance welding equipment has further improved the accuracy of control and achieved welding control from 0.3 mm to more precise. It is worth mentioning that in a National Natural Science Foundation project, my country has conducted in-depth research on "computer simulation and auxiliary design of arc welding inverter power supply structure and parameters", which is an outstanding example of the application of simulation technology in the field of welding equipment, although there are not many related literature.

Experts with 15 years of senior experience in resistance welding process are well aware of the particularity of spot welding power supply. AC spot welders and capacitor energy storage resistance welders have their own characteristics, especially when dealing with workpieces with extremely small thermal inertia, their advantages are more significant. In addition, the computer-aided design system of AC arc welding transformers has also been studied in depth, providing strong support for the optimization of welding processes.

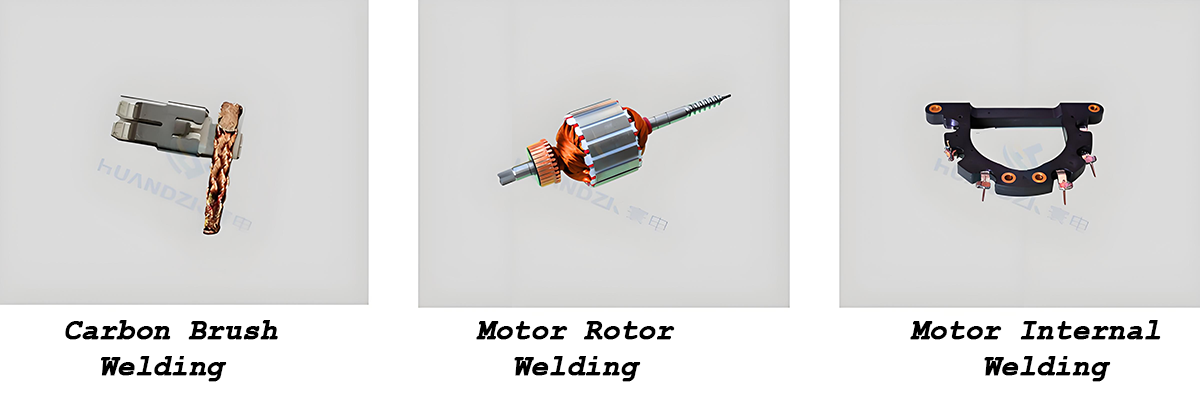

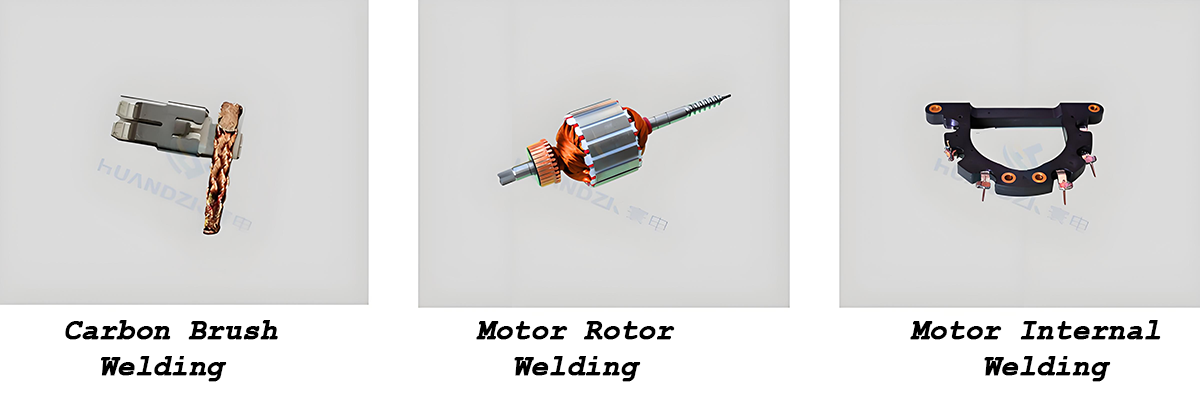

Globally, automation research and development is in full swing, and our equipment, with its stable quality, fully meets the high standards of enterprises. In the factory, we have precision inverter spot welders (butt welders), hot press welders, seam welders,wire mesh welding machine, thermocouple welding machine, etc. with various powers to meet different welding needs. These equipment have less heat analysis during welding, a wide range of applications, and can quickly calculate and supplement the required information according to the welding situation.

The company has brought together a research and development team composed of welding experts, professors, postdoctoral fellows, doctors and other high-quality talents, and is committed to promoting the continuous innovation and development of welding technology. Computer simulation technology, as a perfect combination of modern technology and computer development, is playing an increasingly important role in our research and development process. We firmly believe that through continuous technological innovation and optimization, our spot welding power supply will bring users a more efficient and accurate welding experience.

If you are eager to explore more knowledge or have a strong interest in our products, please contact us via WhatsApp or WeChat. We warmly welcome your consultation and look forward to providing you with detailed answers.