In the evolution of battery spot welding, various types of spot welding machines have been developed, each showcasing unique features and applications. The lithium battery industry has seen significant advancements, transitioning from traditional AC pulse welders to more sophisticated models like energy storage, medium frequency, transistor, and laser spot welding machines. Each iteration improves the efficiency and quality of spot welding.

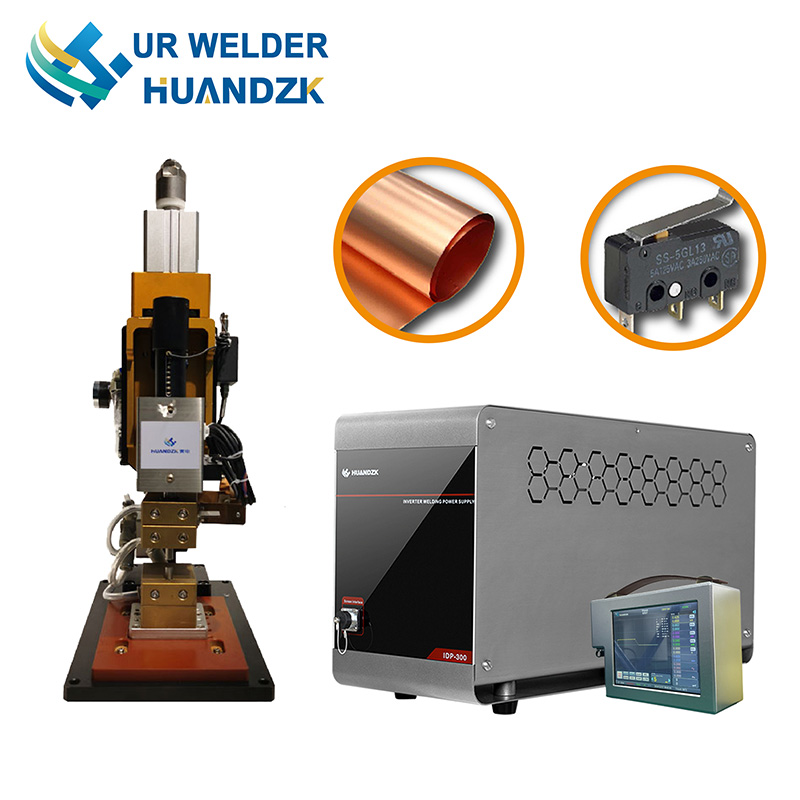

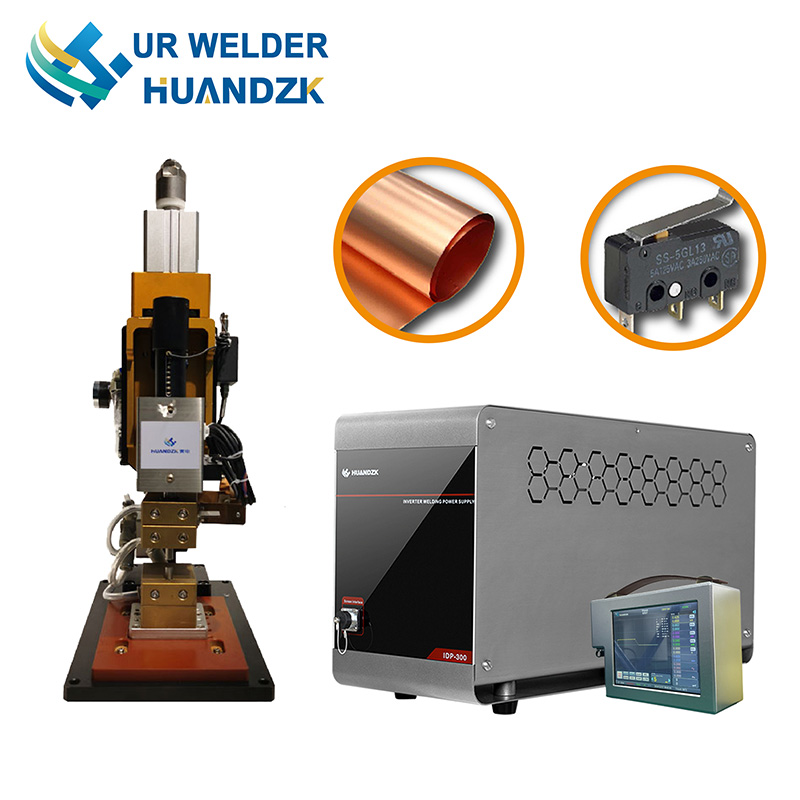

The welding power supply plays a crucial role in these systems. For instance, Huandian's DC inverter precision power supply stands out with its optimized output, enhancing stability and efficiency for diverse welding needs. Despite technological progress, different spot welding machines coexist, each contributing uniquely to production processes.

AC pulse spot welding machines are favored for their low cost and failure rate but suffer from prolonged welding times affecting performance. Energy storage models offer concentrated discharge energy and short welding times but face challenges with high spark scatter and dependency on capacitor charging times, limiting their use in automated settings.

Medium frequency welding transformer solutions convert AC input into stable, low-voltage, high-current outputs suitable for precise resistance welding tasks. Their ability to adjust high-frequency pulse widths according to output currents ensures consistent welding quality, making them ideal for many industrial applications.

Transistor-based resistance welding power supplies eliminate the need for a welding transformer, providing rapid current rise and direct high-frequency current waveform outputs. Though expensive, they offer superior control methods, enhancing welding accuracy and reliability.

Lastly, laser spot welding machines, composed of advanced components like crystals and xenon lamps, provide non-contact welding with minimal preparation, making them perfect for delicate operations such as polymer PACK protection board welding. However, their high price and maintenance costs can be prohibitive.

Overall, while new technologies emerge, existing spot welding machines continue to play vital roles in manufacturing, meeting varied production demands. Huandian’s innovative approach to welding power supply design highlights an important advancement in modern resistance welding techniques, ensuring efficient and reliable battery spot welding operations.

If you are eager to explore more knowledge or have a strong interest in our products, please contact us wechat/whatsapp +86 15117998597. We warmly welcome your consultation and look forward to providing you with detailed answers.