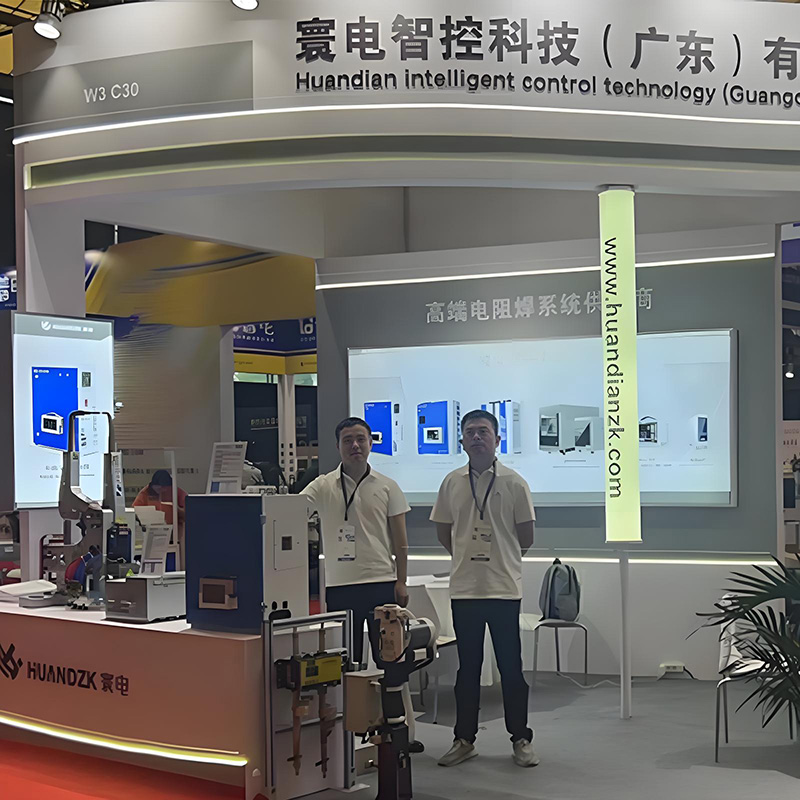

China's best resistance welding power supply manufacturers will bring high-quality welding solutions to the "Automotive Welding and Components Exhibition" held in Shanghai Automotive welding Exhibtion from July 9 to 11, 2025. The exhibition is expected to attract more than 30,000 visitors. We will focus on displaying a series of advanced welding equipment including resistance welding controllers, precision resistance welding power supplies, MFDC (medium frequency direct current), HFDC (high frequency direct current), VFAC (variable frequency alternating current), HD-400B-all-rounds-comprehensive-welding-monitor.html">welding monitors, precision spot welders, etc. at booth W3-C30, which are widely used in automobile manufacturing, electronics, batteries, hardware, compressors, home appliances and other industries.

The resistance weld controller supports multi-stage discharge function, and can set the slow rise and slow fall of each stage separately, effectively solving the problem of welding spatter and optimizing the formation and strength of weld spots. Equipped with rich I/O interfaces, resistance weld controller is compatible with communication protocols such as RS-232, RS-485, and Ethernet, which facilitates the integration of PLC automation systems and industrial interconnection.

The HD-400B welding monitor exhibited this time far exceeds Miyachi's MM-400 in performance, with extremely high sampling accuracy and welding data recording capabilities. Our independently developed welding controller supports 5 operating frequencies (1kHz/2kHz/3kHz/4kHz/5kHz) and 6 control modes, with a built-in welding quality judgment function, which can set upper and lower limits for key parameters such as current, voltage, power, pressure, displacement, etc. and monitor them in real time, automatically identify bad welding and alarm and remove them.

In terms of safety, the system has built-in 22 welding fault diagnosis functions and a complete alarm protection module to ensure stable and reliable operation of the equipment. The welding power supply has powerful quality control and welding traceability functions, with a control accuracy of 0.2ms. Inverter welding power supply welding equipment has the advantages of low heat generation, beautiful welds, strong tensile force, small damage, and low defective rate.

Resistance welding power supply is widely used in a variety of welding equipment such as spot welders, butt welders, roll welders, seam welders, and mesh welders. During the exhibition, we will have in-depth exchanges with global customers on the advantages and application scenarios of welding solutions to help customers improve production efficiency, reduce operating costs, and build a new future of intelligent and digital welding.