Do you feel helpless in the face of the problem of medium frequency spot welding machine overheating? Indeed, overheating of the machine not only affects the welding quality, but also may bring serious safety hazards. Today, let us explore the root cause of the medium frequency spot welding machine overheating and find a solution.

The six main culprits of medium frequency spot welding machine overheating are revealed:

Abnormal circulation cooling system: First, make sure that the circulating cold water system is operating normally, the chiller is turned on, and check whether the water channel is unobstructed to avoid blockage and poor heat dissipation.

Insulation resistance problem: Check whether the insulation resistance between the electrode holder and the machine body meets the standard to prevent local short circuit caused by poor insulation, which is often a small but critical negligence that causes voltage overheating.

Improper water flow parameters: Adjust the water inlet pressure, water flow and water supply temperature to the appropriate range to ensure the best cooling effect.

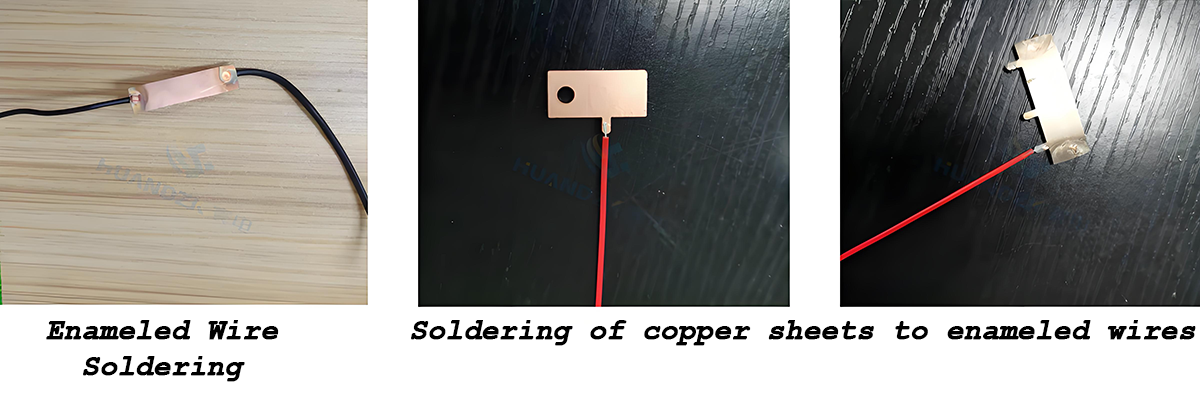

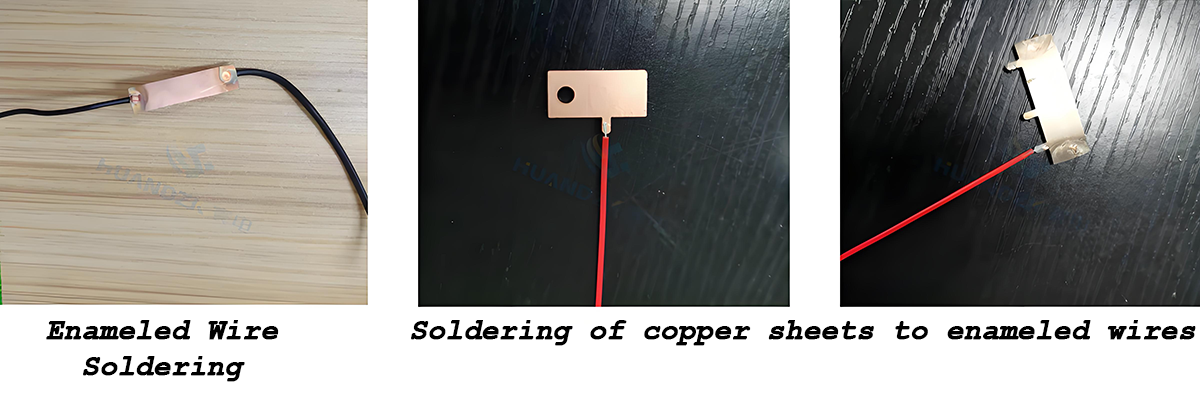

Contact surface oxidation: Carefully check the contact surface of the copper soft link, electrode arm, electrode rod and electrode head to see if there is serious oxidation, which will increase the contact resistance and thus aggravate the heating.

Electrode head wear: Evaluate whether the cross section of the electrode head is severely worn due to long-term use. Excessive wear will cause the welder to overload and cause overheating.

Load duration rate exceeds the standard: According to the thickness and specifications of the welded product, reasonably set the current of the medium frequency spot welder, and monitor whether the load duration rate is kept within the safe range.

IDP series inverter DC welding power supply: technology-led, excellent quality

As a star product of Ur Welder, the IDP series inverter DC welding power supply combines the excellent quality of imported components with the most advanced inverter power supply technology and DSP electronic control technology. It not only has high-precision control capabilities (0.2 milliseconds), but also achieves multiple advantages such as low heat generation, low workpiece damage, beautiful solder joints, high welding strength, strong stability and low defective product rate. In addition, its powerful welding quality control capabilities, data monitoring and traceability functions provide strong support for the optimization and improvement of welding processes.

We focus on the research and development and sales of high-efficiency and energy-saving resistance welding machines, automated welding equipment and industry-specific welding equipment, and are committed to providing customers with the best welding solutions. If you have any needs or questions about medium frequency spot welders or other welding equipment, please feel free to contact us and we will serve you wholeheartedly!