In the working environment, the dust problem generated by high-frequency

spot welding cannot be ignored. This is not only related to the cleanliness of the working environment, but also directly related to the health and safety of the operators. During the welding process of high-frequency spot welding, the metal evaporates due to high temperature to form smoke. These smoke condenses in the air and turns into dust, and these dusts often contain toxic components. So, how to effectively reduce the generation of these dusts at work?

In order to reduce the harm of dust and harmful gases during high-frequency spot welding, we can start from the following key aspects:

(1) Optimize welding materials: First, we should try to choose low-dust and low-toxic welding materials. For example, components such as fluorite and water glass in traditional low-hydrogen welding rods are prone to cause a lot of dust and toxic gases. Therefore, we should try to choose substitutes with lower dust generation and smoke toxicity.

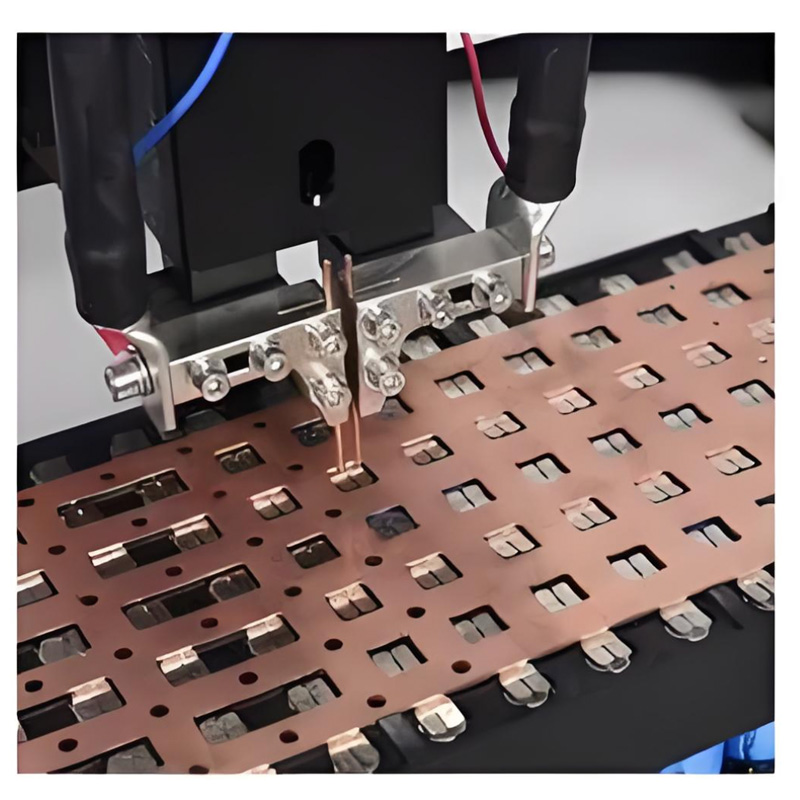

(2) Improve the level of welding automation: By improving the mechanization and automation of welding, we can effectively reduce the dust problems caused by manual operation. Automated welding not only improves work efficiency, but also can more accurately control the welding process, thereby reducing dust generation.

(3) Strengthen ventilation: Good ventilation is the key to reducing welding dust. We can use ventilation equipment to introduce fresh air into the workplace and expel air containing harmful substances in time. Whether it is natural ventilation or mechanical ventilation, whether it is full ventilation or local ventilation, it should be flexibly selected according to the actual situation to ensure the air quality of the working environment.

In addition, when using medium-frequency spot welders and other welding equipment, we must strictly abide by the safety operating procedures of the equipment. These procedures are usually listed in detail in the equipment's instruction manual, including requirements for equipment installation, commissioning, operation, and maintenance. For flammable and explosive equipment, extra care should be taken to ensure safety during operation.

In summary, by optimizing welding materials, improving the level of welding automation, and strengthening ventilation, we can effectively reduce the dust problem generated by high-frequency spot welders during welding and create a safer and healthier working environment for operators.

Tips:Our core products include ultra precision welding power supplies, precision inverter welding power supplies, high power high frequency DC welding power supplies, high frequency

transformers and other hardware essentials; at the same time, we also provide intelligent solutions such as multi functional

HD-400B-all-rounds-comprehensive-welding-monitor.html">welding monitors, welding networking group control systems and welding quality monitoring systems. If you are interested in any of the above products or need further information, please feel free to contact us, or click on the lower right corner to follow our major social platforms.